Who We Are

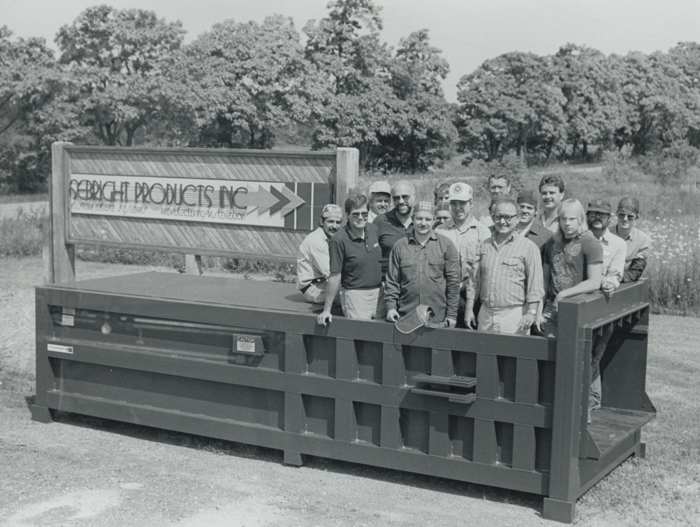

Since 1984, Sebright Products, Inc. has been designing and manufacturing waste handling and recycling equipment. Sebright Products was founded in 1978 and Incorporated in 1984 by Brent Sebright, President, and Lee Murray, Vice President, in Hopkins, Michigan. Since then, our unwavering dedication to manufacturing the highest quality industrial equipment in the industry has earned Sebright Products a reputation for excellence. Manufacturing rugged, reliable equipment is only the beginning of our commitment to our customers: we also offer turnkey installations and after-the-sale service that is second to none.

Other than our knowledge, dedication, and character, the real incentive to invest in a piece of Sebright Products’ equipment is the long-term reliability you will achieve with your capital investment. With a relentless focus on engineering excellence, Sebright Products Inc. designs and manufactures state-of-the-art equipment tailored to meet the diverse needs of our global clientele. Our team of experienced engineers and technicians utilizes cutting-edge technology and industry-leading practices to deliver products that set new standards for performance, durability, and reliability.

Building equipment to withstand high-volume and heavy-duty industrial applications has also allowed us to build the best equipment for everyday applications. With a presence spanning continents and industries, Sebright Products Inc. has had a significant impact on waste management practices worldwide. Our solutions are trusted by businesses, municipalities, and organizations of all sizes, from local enterprises to multinational corporations. Together, we are driving positive change and shaping a more sustainable future for generations to come.