There are three process zones to a Belt Filter Press: gravity, wedge, and high/pressure/shear zones. First, the sludge or slurry is introduced to the filter in the gravity zone. This typically happens after a chemical flocculent or polymer has been introduced and mixed into the slurry to release water and form larger particles. Finally, the slurry is spread across the usable area of the filter and is contained by running off the filter sides with rubber seals. Typically, plows or chicanes are located on the upper surface of the filter belt to move the sludge solids and promote drainage. On the lower side, the filter belt is typically supported by a grid of replaceable plastic material.

Many Belt Filter Press designs place these support grids too far apart (6-10 inches), and on some, the supports are too wide, blocking the drainage of liquids from the filter belt. However, Bright’s superior design features ½-inch-wide UHMW plastic strips spaced 2.5 inches apart. As a result, this promotes superior drainage by breaking surface tension on the filter without unnecessarily blocking the exiting water. Additionally, the close grid also provides better support for the filter, creating a tighter seal with the rubber containment pieces.

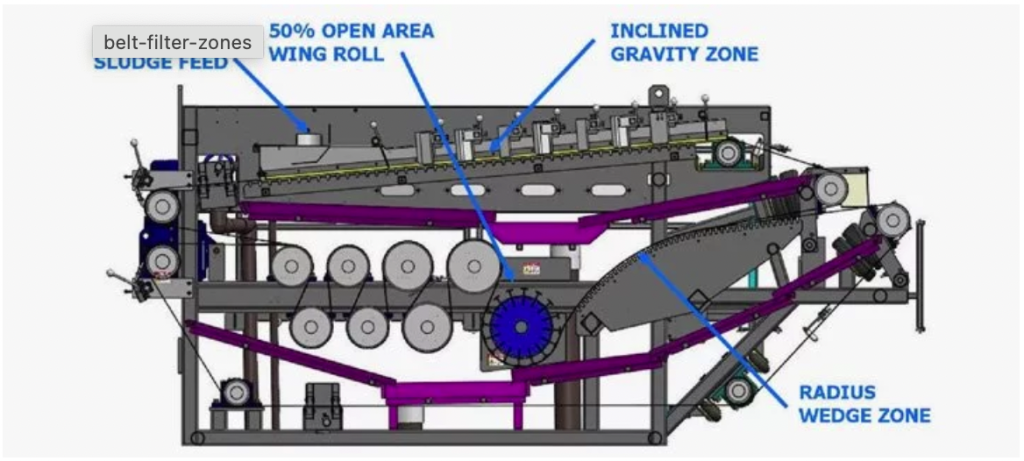

INCLINED GRAVITY ZONE

Second, Bright Belt Filter Presses feature an inclined gravity section, unlike most competitors, which have a level gravity zone. The sludge feed box is lower than the discharge end of the gravity zone. Therefore, this promotes better dewatering by keeping the water-laden sludge near the feed box and carrying the solids up to the discharge only after most of the water has drained through the filter. As a result, this gives the gravity zone more effective dewatering time than is possible with a level gravity deck. It also enables higher production rates.

PATENTED WEDGE ZONE

Third, the wedge zone is where the upper and lower filter belts meet and envelope the slurry on two sides. As a result, Belt Filter Presses have a patented radius wedge zone that applies gentle pressure on solids in the slurry that provides superior conditioning prior to entry to the High Pressure/Shear Zone and does not require any operator adjustment.

HIGH PRESSURE/SHEAR ZONE

Finally, in this zone, the filter belts are wrapped around steel rollers that progress from a large diameter to a smaller one, and as the diameter of the roll decreases, the pressure on the sludge increases.

The first pressure roll on a Bright Belt Press is a patented Wing Roll, uniquely engineered with a 50% open area and a convex inner surface. This innovative design channels liquid outward, allowing it to drop beyond the filter belt and preventing re-wetting, thereby improving dewatering efficiency. We construct our rolls using a triple stub plate design and stainless steel, eliminating the need for any roll coatings.