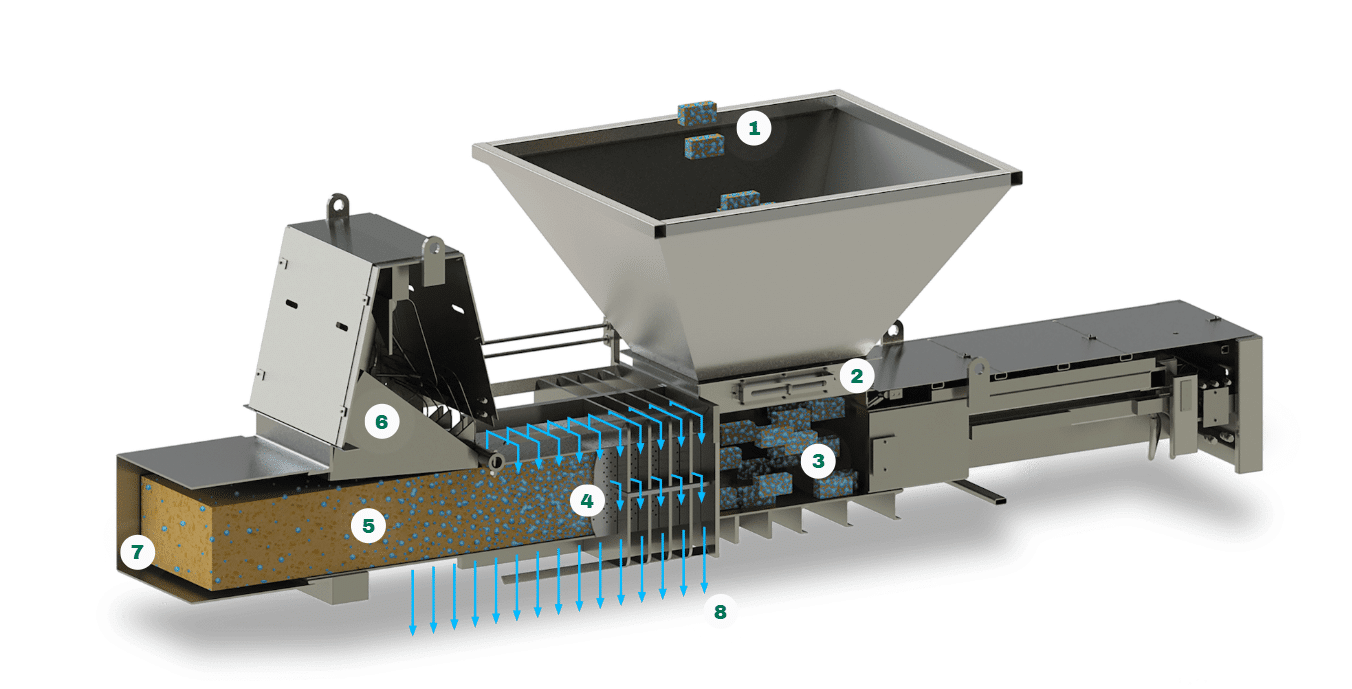

Optimize Dewatering with Sebright High Density Extruders

The High Density Extruders are used to extract liquids from various types of industrial refuse byproducts or to remove liquids from commonly used packaged products and beverages. Tested and proven time and time again, the High Density Extruder is the best performing, most efficient and most reliable ram press available today.